Posted at 09:39h

in

3D Capture

The beauty of photogrammetry is the ability to create a 3D model from ordinary photographs. This opens up great opportunity to people who could use such models for 3D printing or digital media but don't know how to design with CAD. How could this be better? Well, you don't even have to take the photos yourself.

If you can download photos, you can 3D model. Try Google Images, Flickr, etc., to gather a collection of photos of a given subject. Upload them into software like Memento--hey presto, 3D model. Check out the following Manhattan model I made while developing this 3D printed sculpture (photos from Google Earth):

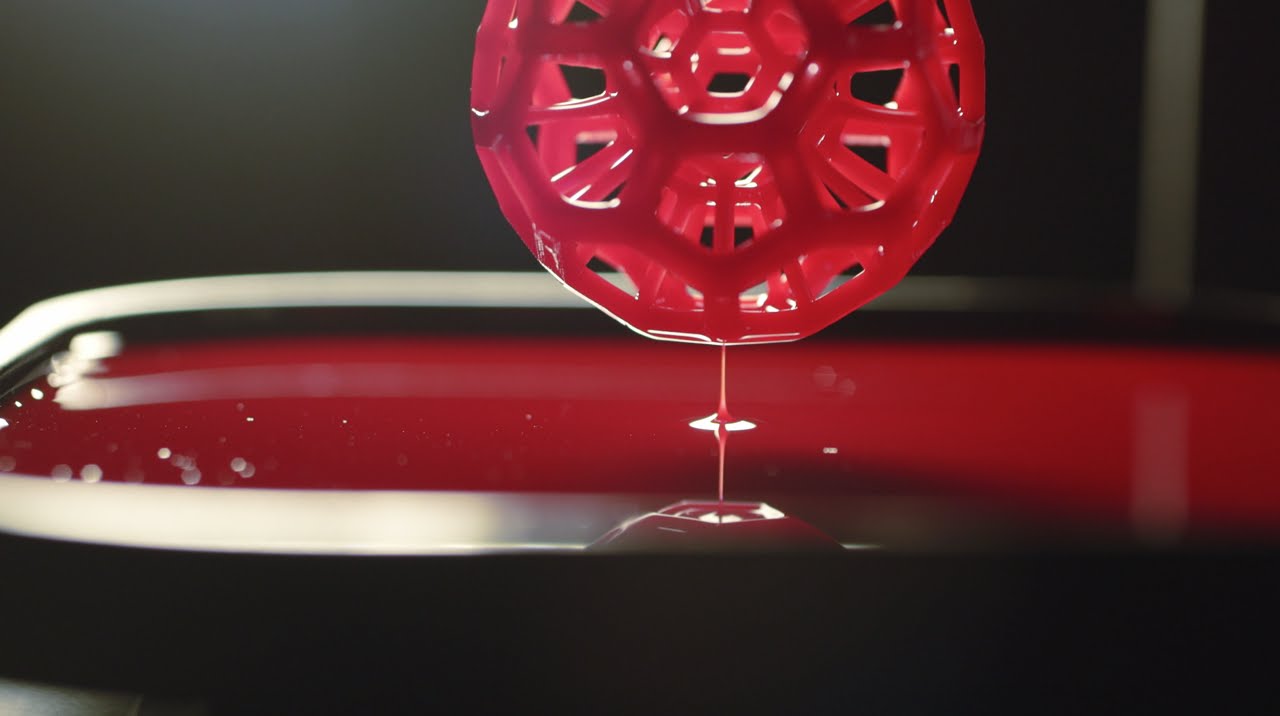

Similarly, I'm modeling a Gaudí designed gate in Barcelona via crowd-sourced imagery. Finca Güell:

Solutions are either mechanical or material.

Solutions are either mechanical or material.